Today's HoursThursday 8:30AM - 6:00PM

| Monday | 8:30AM - 5:00PM |

| Tuesday | 8:30AM - 5:00PM |

| Wednesday | 8:30AM - 5:00PM |

| Thursday | 8:30AM - 5:00PM |

| Friday | 8:30AM - 5:00PM |

| Saturday | 9:00AM - 12:00PM |

| Sunday | Closed |

Farm King

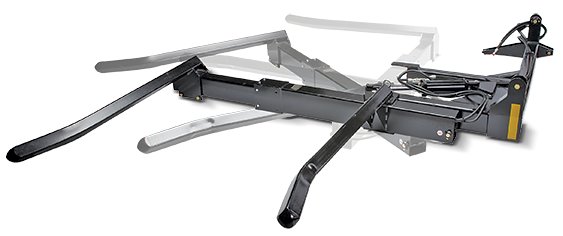

Farm king - ROUND BALE CARRIER 1450

-

ID # 35174597

- Back ID:35174597

- Book a Demo

- Get Directions

|

BALE MOVING JUST GOT A LOT EASIER WITH FARM KING ROUND BALE CARRIERS, BALE CARRIERS THAT REPLACE THE OLD WAY OF MOVING BALES WITH A FRONT-END LOADER AND A FLAT-DECK. PICK, HAUL AND UNLOAD ROUND BALES WITH SPEED AND EFFICIENCY, WHETHER MOVING BALES FROM THE FIELD OR BACK TO THE FARMYARD. Heavy duty construction means the bale carriers are robust, yet designed to be affordable with gentle bale handling and easy maintenance. Rugged durability, proven performance and easy unloading minimizes bale damage and reduces handling costs. A hand-held control works with the tractor remotes to operate all the functions of the bale carrier. The bale carrier uses two sets of tractor hydraulic outlets. Gentle yet rugged pickup arms place bales on the deck where a pusher, powered by two hydraulic motors, slides the bales back on graphite coated carrier beams. This means efficient bale handling, less stress and more bales moved each day. |

| A single-row carrier can accommodate seven 5' x 6' bales, or eight 4' x 6'. Equipped with a single-sided pickup arm. |

THE RIGHT SIZEThe right size and the right features The 1450 round bale carrier can carry seven 5' by 6' bales weighing up to 900 kg (2,000 lb) each in a single row. The double wide Farm King 2450 has twice the capacity. Ideal for hilly terrain the shorter, more maneuverable 2400 can carry ten 4' x 6' round bales. Heavy-duty construction means the bale carriers are robust, yet designed to load and unload bales quickly and without damage. Lower bale handling costs and simple maintenance help improve the profitability of your hay. |

DECKThe heavy duty undercarriage and tandem walking beam axles ensure reliable transport to the unloading area. To unload, the operator tilts the carrier deck using the tractor control. Once the rear of the deck is on the ground, the pusher, controlled with the hand-held remote, unloads the bales in tight end-to-end rows. |

PUSHERAfter bales are lifted onto the deck, a pusher moves the bales rearward. The pusher has two settings that are selected on the hand held remote. The operator can choose the most efficient speed and torque for varying conditions: ‘high’ for dry hay and straw; ‘low’ provides additional torque for wet or high moisture silage bales, and the pusher moves with less speed. |

PICKUP ARMS

|

Standard ArmThe 1450S, 2400S and the 2450S feature standard pickup arms. A bale deflector is built into the outer fork which means bales can be picked up from either the ‘end-on’ or ‘side-on’ position. This allows the operator to approach the bale from any angle. Model 2400 features a right-hand side pickup arm while model 2450 is equipped with both left-hand and right-hand side pickup arms for even more maneuverability and convenience. Model 2400 features an optional bale stop indicator for use with more narrow bales (4'). |

Rotating Pickup ArmThe 1450R and 2450R are equipped with rotating pickup (RPU) arms with forks that hydraulically squeeze, rotate and lift bales onto the deck for ‘side-on’ picking. This allows the operator to follow the travel of the baler. |